CAPSIM production strategy tips-overview, capacity utilization, expansion and automation

CAPSIM production tips summary

- Production capacity improvement

- Production capacity scheduling

- Production capacity expansion rule

- Production capacity for new product

- How many units of a new product should you produce?

- When should you sell capacity

- Which product’s capacity should you sell?

- How many units of capacity should you sell?

- Automation

- Conclusion

>>>FREE capsim answers 2022<<<

>>>FREE Complete Compxm answers 2021<<<

>>>FREE Expert 950+/1000 compxm answers 2022<<<

>>>FREE CAPSIM 5 points cheat sheet to win everything 2022 <<<

>>>FREE 900+ 10 points tips to win capsim 2022 error free<<<

What is production in CAPSIM?

Functionality that enables one to order production, capacity change, and automation

In CAPSIM, the production section of the simulation carries several functions, including assigning units to produce in a given round, change production capacity, and change the automation level. Although it seems less complicated compared to other sections of CAPSIM, a little error in this section can lead to excess inventory, excess capacity, and even emergency loans. Therefore, you need to set rules to guide you when making decisions in this section.

Capsim production schedule formula

My formula for capsim production schedule analysis has only a few items, including next year’s segment growth rate, unit sold(market share), and my confidence based on how well I made R&D and marketing decisions as well as TQM.

The confidence also depends on the segment dynamics. For example, in low end and tradition, price plays a major role. For instance, If I don’t want to charge the lowest price, it means I’ll have to forego some demands.

|

Segment |

Demand forecast formula |

Use this formula only if you meet the following |

|

Traditional |

Last round unit sold *{1+ next year’s segment growth rate}+300 Add 50 if only you and one more competitor is using TQM strategies extensively

|

|

|

Low-end |

Last round unit sold *{1+ next year’s segment growth rate}+300 Add 50 if only you and one more competitor is using TQM strategies extensively

|

|

|

High-end |

Last round unit sold *{1+ next year’s segment growth rate}+200 Add 50 if only you and one more competitor is using TQM strategies extensively

|

|

|

Size |

Last round unit sold *{1+ next year’s segment growth rate}+200 Add 50 if only you and one more competitor is using TQM strategies extensively

|

|

|

Performance |

Last round unit sold *{1+ next year’s segment growth rate}+150 Add 50 if only you and one more competitor is using TQM strategies extensively

|

|

Capacity improvement

The market size per segment increases as the game progresses. That means you need to increase the capacity to meet the market demand. Also, capacity expansion allows you to produce cost-effectively, thus allowing you to earn more. This is possible since whenever you are producing in the second shift, you pay twice more in labor costs. Apparently, increasing capacity reduces the labor cost.

Increasing your capacity should not just happen. There should be triggers that prompt you to increase capacity. Capacity expansion triggers should also inform you of the size of the capacity to purchase in a given round per product.

What is the best capacity expansion rules that can work for anyone?

Usually, I only increase capacity when plant utilization exceeds 150%. And the size I purchase depends on the past rounds sales increase. For example, if every next round sales grew with an average of 200(000) units, I’ll order an additional 300(000) units capacity. Doing so usually gives me an advantage of 100(000) to meet surge in demand in next rounds.

Capacity for new product

When you introduce a new product, you need the capacity to start producing them. If you order R&D for a new product in round 2 and it is estimated to come out in round 3, you need to order capacity for it in round 2.

So how much capacity should you order for the new production?

It depends on the segment where the new product is being introduced to. However, in many decisions that I have made, I only introduce new products in high-end, size, or performance segments.

If you strategy sounds similar to mine, never orders capacity more than 350(000) for a new product .The reason for such decision is that the product is new and high end, size and performance segments do not have large market sizes compared to tradition and low-end segments. Therefore, producing too much may end up in inventory which is expensive to store. Besides, you may not have done a good job in marketing especially in sales to guarantee good accessibility that would assist in generating large sales for new products.

How many units of a new product should you produce?

No more than 350(000). You should only produce 350 (000) units if you already have the accessibility of 65% and above. You also need to spend at the latest 10000 in the promotion and 1500 in sales budget to at least sell most of 350(000) units.

When should you sell capacity

First, when you want to discontinue a product, sell all the capacity but keep 1(000) unit. This will ensure that your product is not terminated; hence you can redesign it later and sell it in a different segment.

You can also sell capacity when you have excess loans to service, and your credit rating is very bad. This means you cannot take a substantial amount of loans. Since you are making losses, your stock may not be doing well hence cannot generate substantial investment capital. In this case, the best option is to sell off some of capacity units to finance production activities.

Which product’s capacity should you sell?

Look for a product in your portfolio that is dong very bad. “Doing bad” means a product that constantly have the lowest contribution margin and highest inventory at hand. If a product has inventory higher than 1000(000) and still has the lowest contribution margin, sell a section of the production capacity to finance your business activities. Do the same for other products.

How many units of capacity should you sell?

Take your current market share of a product you want to sell its capacity, add the maximum you expect to sell in the next two rounds. For example, if your current market share for a product X is 1500(000), and you expect to sell 300 more in the next two rounds, do the following calculation to determine the size of capacity to sell.

Market share in the round (y+2)=1500+300

Capacity with maximum utilization=1800/2=900

If product X have an inventory of 1000, it means next round you will produce less than 700 to meet the demand. If you are already having a capacity of 2000(000), it is prudent to sell at least 900 units and buy later as demand increases.

When selling capacity, think about future growth. Sell, but remember to reserve some to cover for a surge in demand.

Automation

In the first two rounds, increase automation by 2 units for tradition and low-end products. Concurrently, for high end, performance and size increase by 1 unit. When you are not increasing capacity, increase automation. That means, in a particular round, you can be increasing capacity for some products while increasing automation for others. By round 4, ensure your traditional and low-end products have automation of at least 7 while products in high end, size, and performance have at least 6. Increasing automation is important since it assists to reduce labor costs.

Conclusion

- Make rules for capacity expansion-don’t just expand

- Automate low-end and traditional production faster than size, performance and high-end

- Sell capacity when you are making losses, have bad credit rating and stock prices plummeting

- Also, sell capacity if it does not add any value to your company, i.e., in case of excess inventory

- When selling capacity, sell for the one with the highest inventory and lowest contribution margin

- Don’t just sell capacity, think about the possibility of a surge in demand in future

Also check

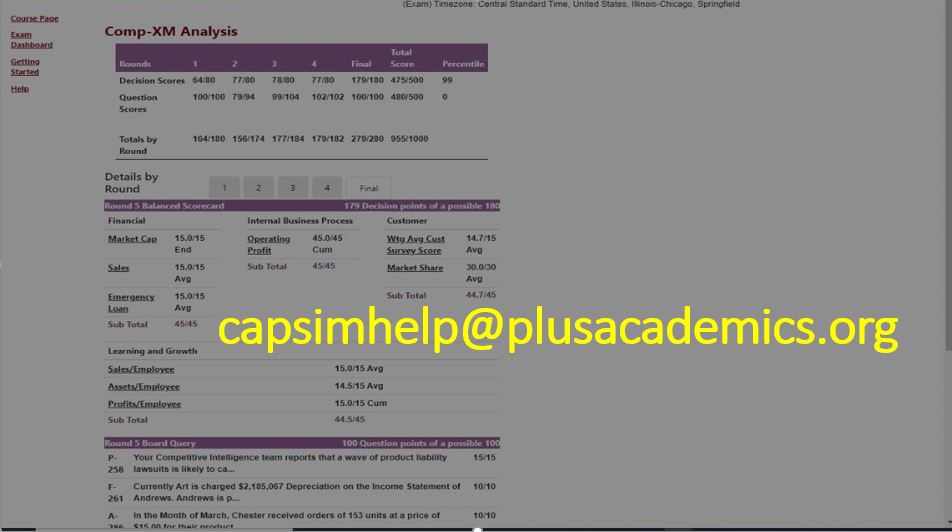

COMPXM tips to earn highest points in COMP XM exam

Compxm answers 2020

How to Win Capsim Competition